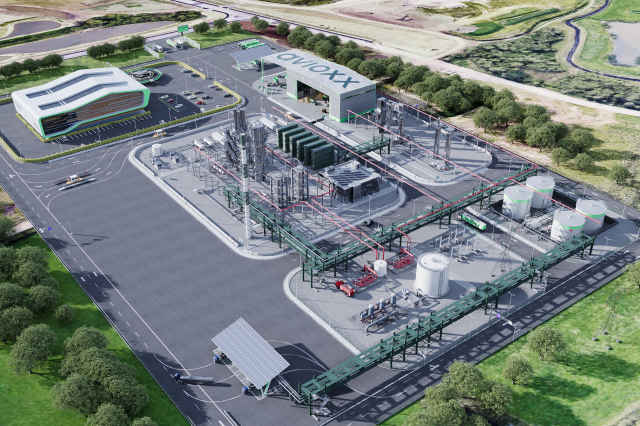

Project Eden: 200 TPA Modular Plant

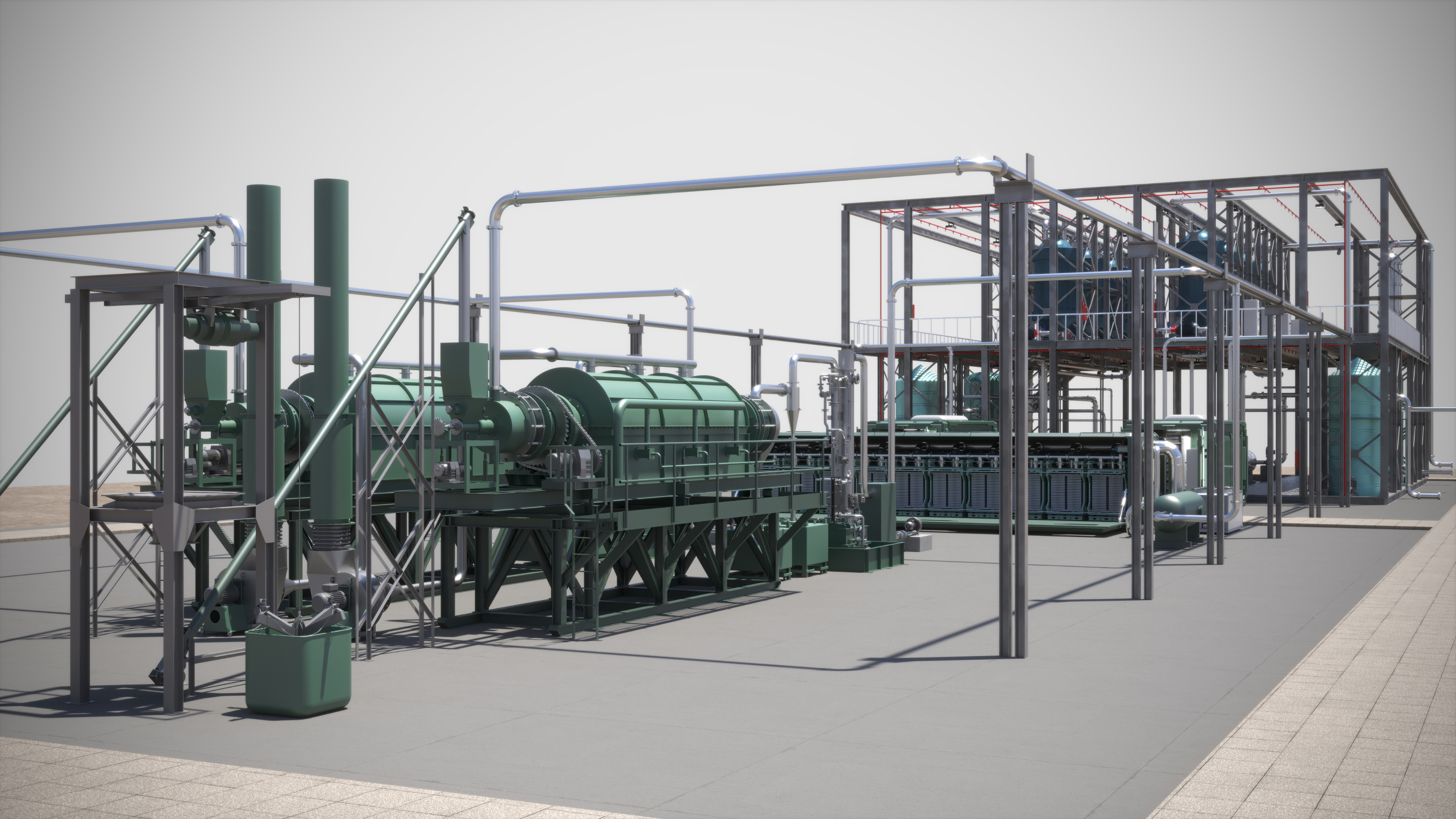

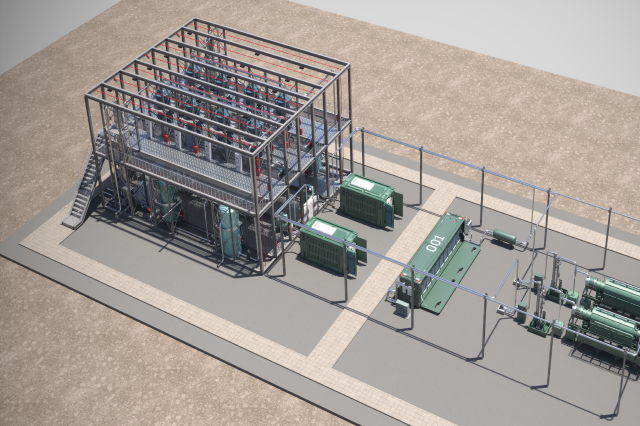

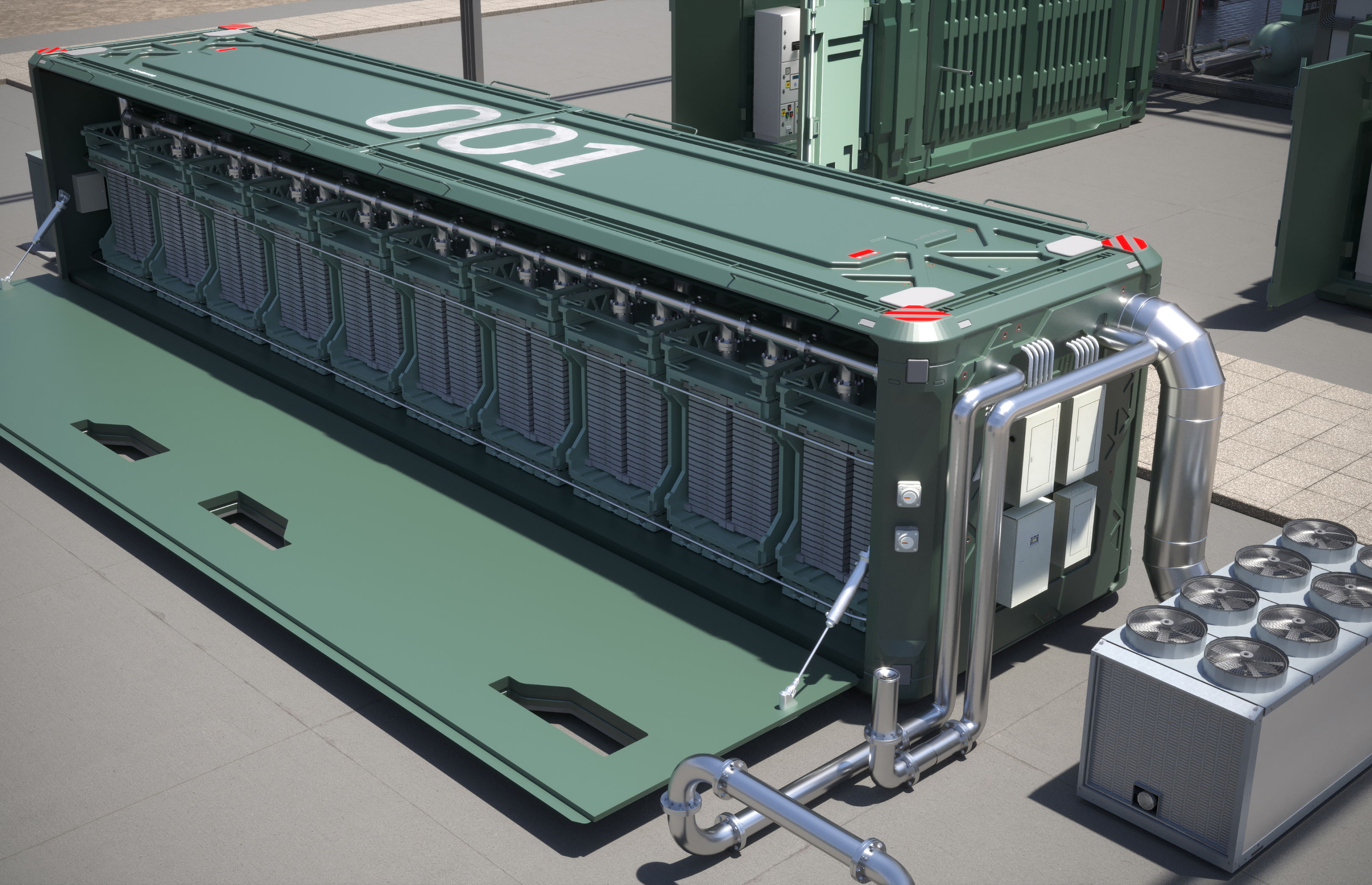

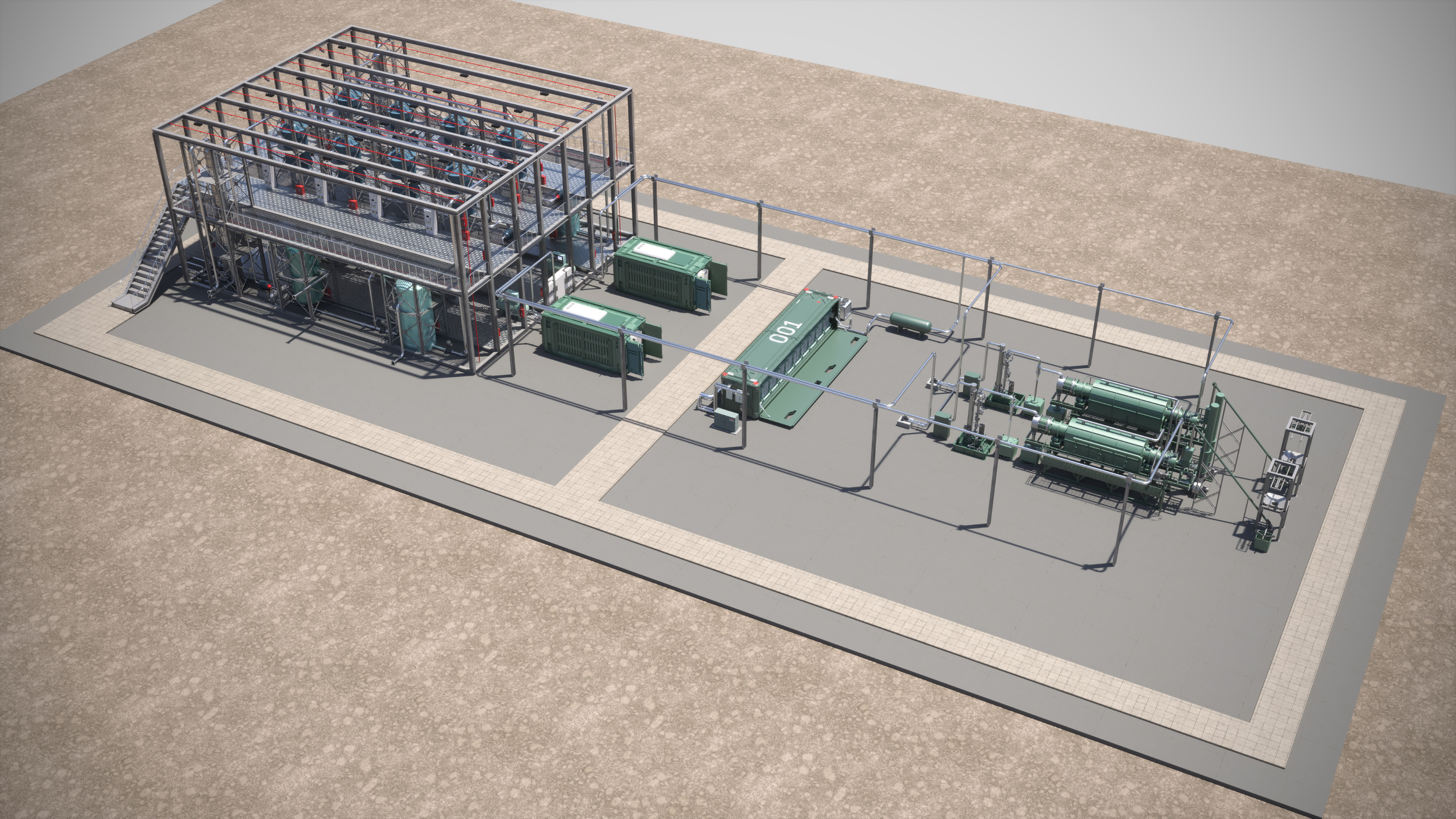

Our plant’s modular architecture facilitates rapid scaling, mobile deployment, and reduced downtime through interchangeable reactor modules.

Annual production volume

Waste feedstock consumed

Plant size

CO2 reduction

The modular design allows for easy scaling and adaptability, making it suitable for deployment in remote regions and on-site at airports, bringing sustainable fuel production closer to the point of use.

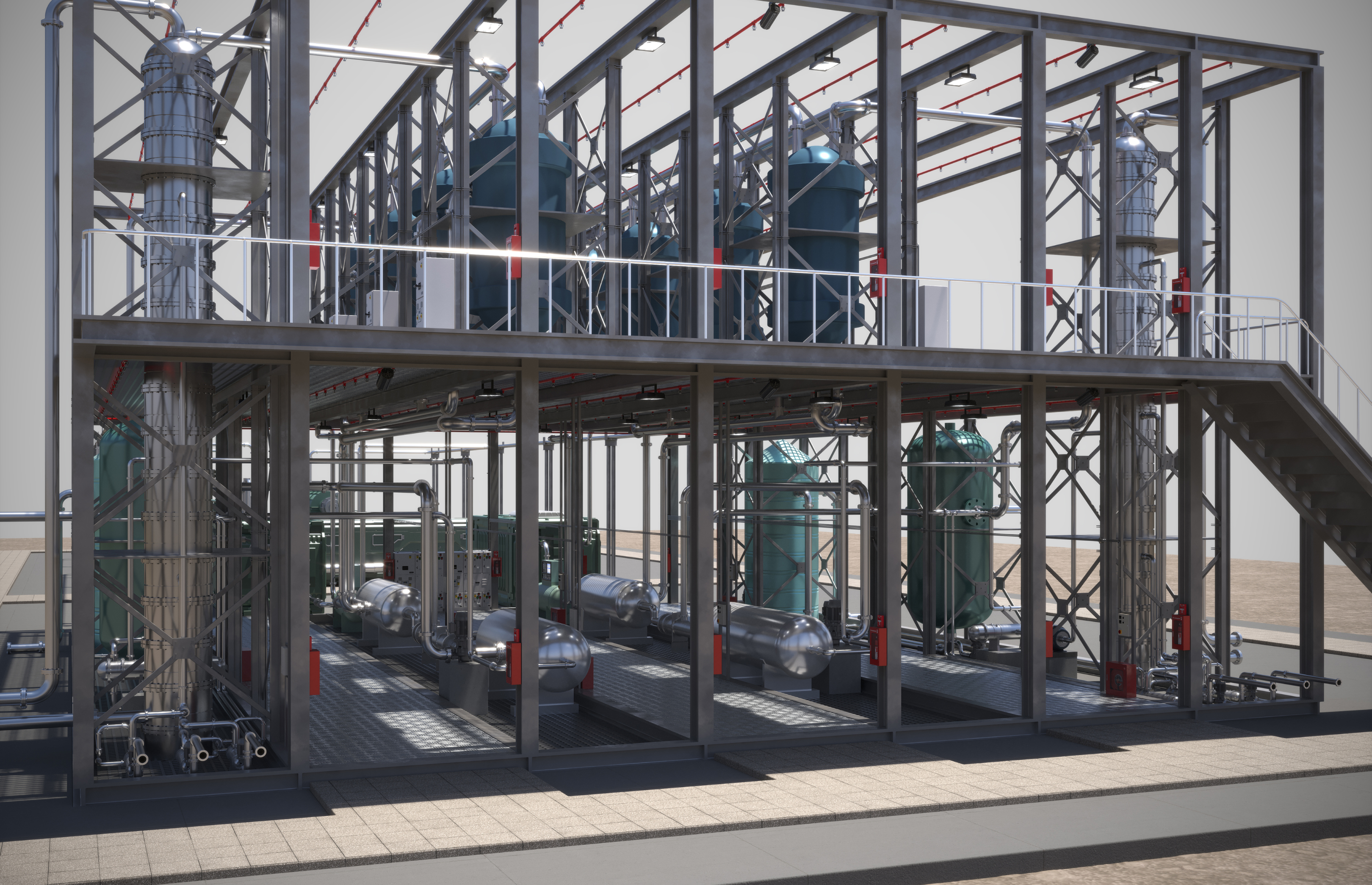

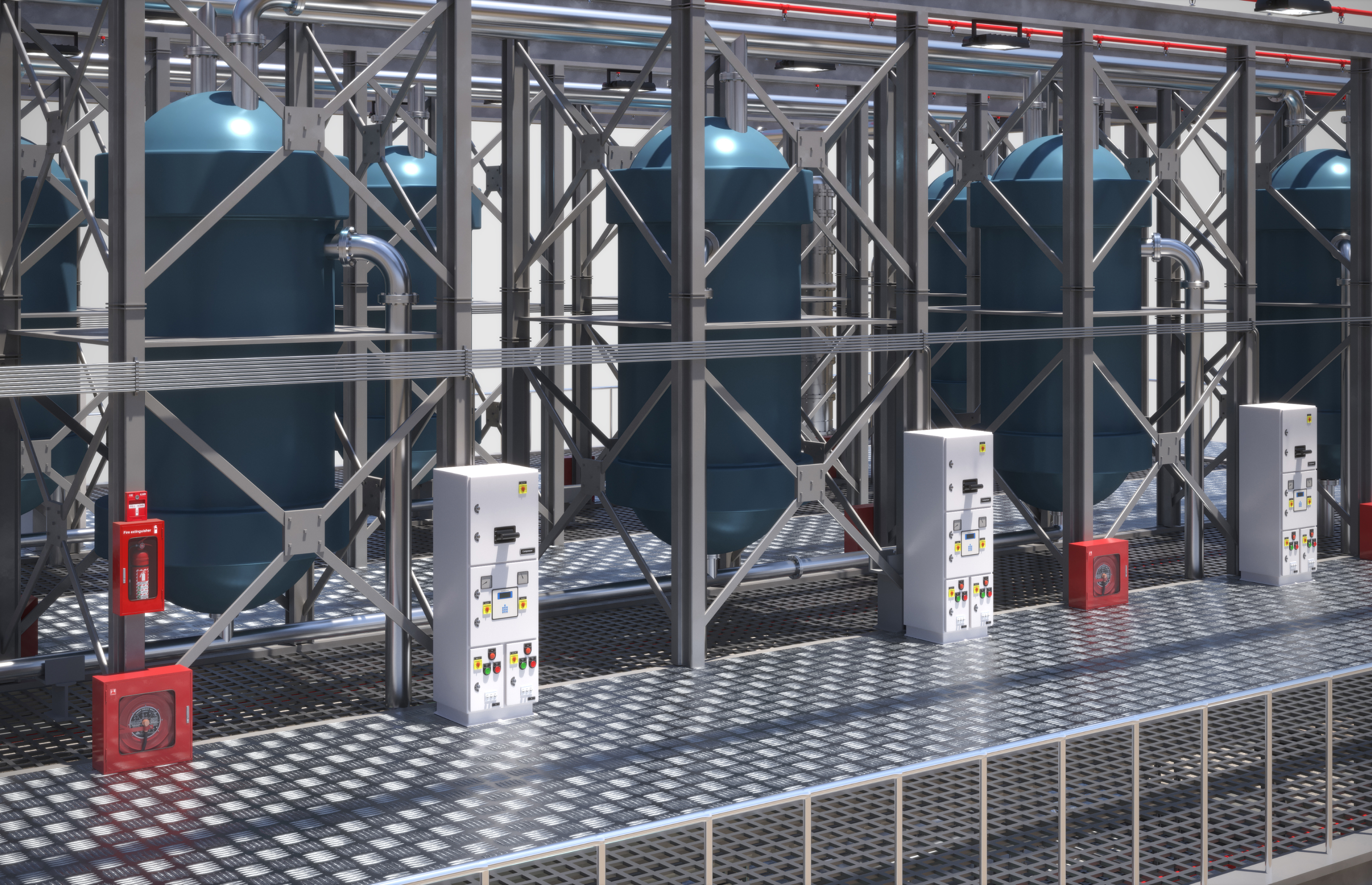

The Modular Plant integrates four advanced reactor systems to maximise efficiency and sustainability. A Pyrolysis Unit converts waste into synthesis gas on a compact scale, while a Solid Oxide Fuel Cell generates 375 kW of electricity from this gas. Electrolysers split water into hydrogen and oxygen, enhancing fuel synthesis, and a Fischer-Tropsch Reactor refines the process by converting synthesis gas and hydrogen into high-quality synthesised crude.

Together, these technologies create a highly efficient, scalable solution for sustainable aviation fuel production. Situated in Northwest England, our first small modular plant leverages the region’s industrial infrastructure, enabling efficient deployment and integration into existing systems. Supported by leading partners and equipment suppliers, this futuristic plant represents a significant advancement in sustainable fuel technology.