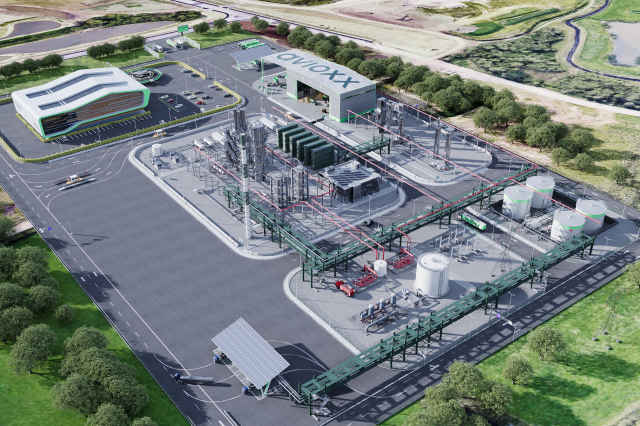

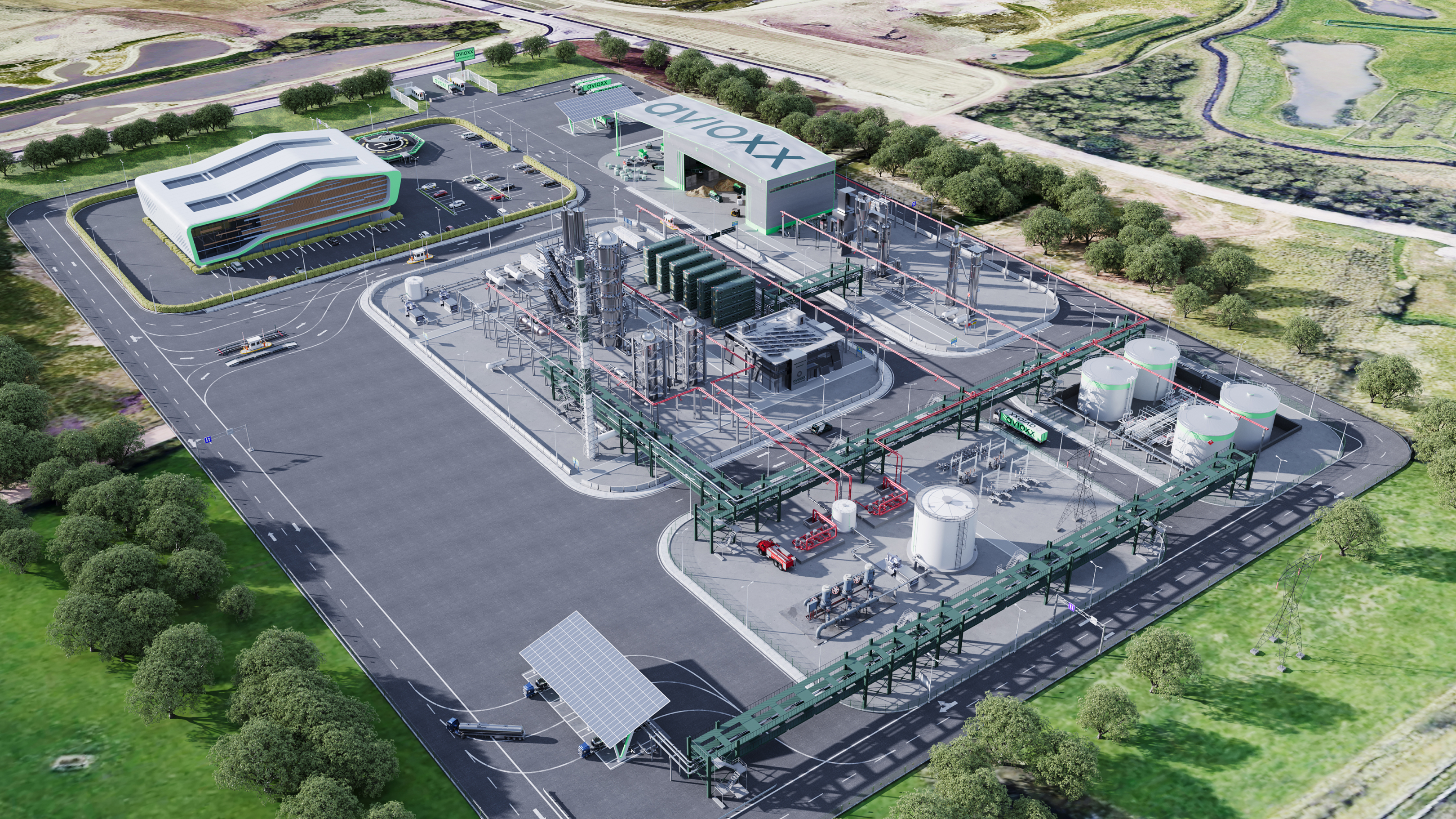

Avioxx Genesis – 32,000 TPA

Our first commercial-scale plant will be based in Cheshire, Northwest England, leveraging the region’s advanced petrochemical infrastructure.

Annual production volume

32k TPA

Waste processed

250k TPA

External energy input

0 mWh

CO2 reduction

429k TPA

All statistics are estimates and subject to variation

This facility serves as a blueprint for future Avioxx refineries, setting the stage for rapid expansion.

Our facility incorporates a 69 MW electrochemical system to enhance hydrogen production, optimising gas ratios for the Fischer-Tropsch process. This innovation boosts efficiency while reducing emissions, making our SAF production cleaner and more cost-effective.

Avioxx integrates automation, machine learning, and AI to

Avioxx plans to build at minimum 10 UK plants, cutting 5 million tonnes of CO2 annually, equal to removing 200 billion plastic bottles, 83 million air miles, or 12,000 London to New York round trips.

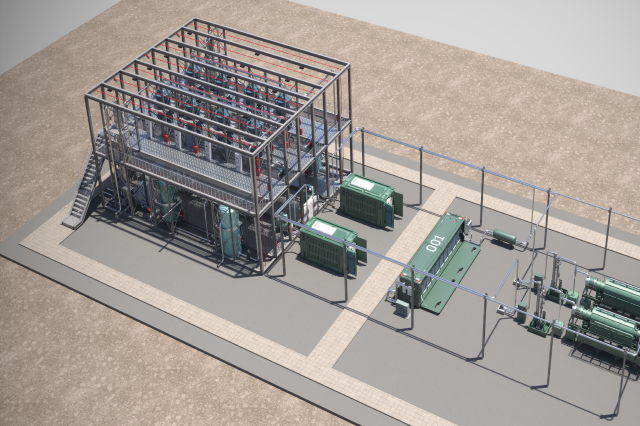

Waste sorting and Fischer-Tropsch reactor

Solid Oxide Fuel Cells and gas cleanup

Full aerial view of the large pilot plant

9Mw of Solid Oxide Fuel cells