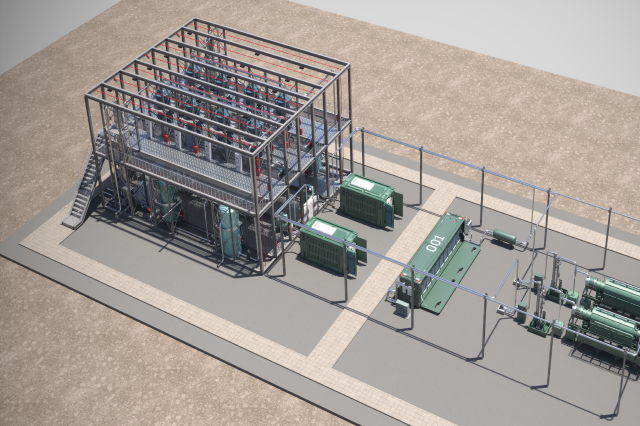

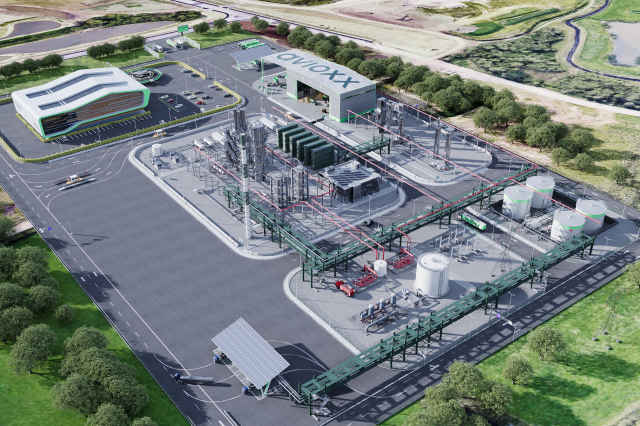

The Avioxx process comprises two distinct elements which are integrated to provide an optimised, flexible process.

Our unique four stage process generates a cost-competitive sustainable aviation fuel (SAF) to the standard of stringent international specifications while utilising a wide variety of waste hydrocarbons and plastics.

Phase 1 of the process, covered by Patent GB2431511, was initially developed as an innovative means to produce electricity and hydrogen from waste hydrocarbons. This stage generates an output stream of concentrated CO2, which can be captured and stored with relative ease.

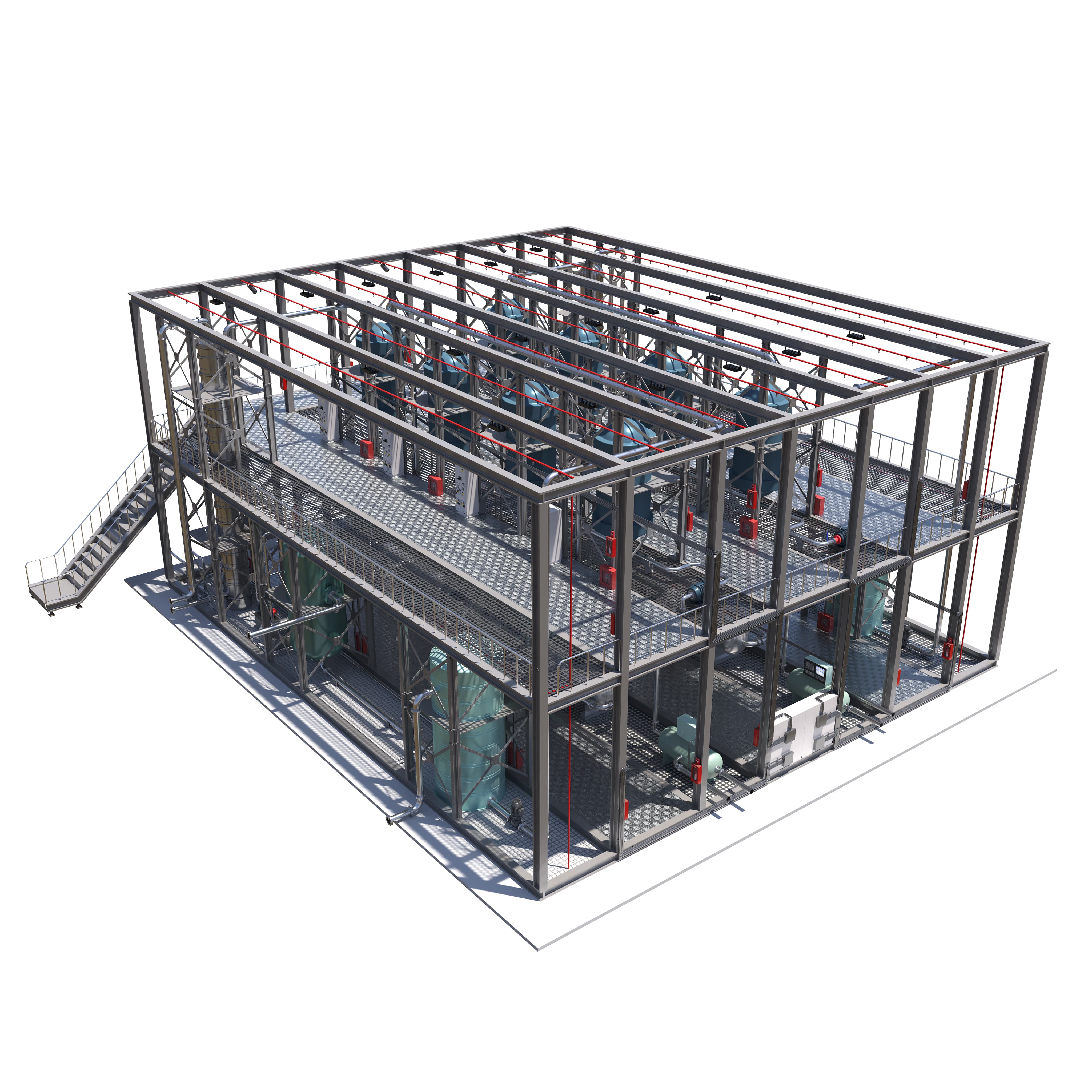

Phase 2 of the process relies on the well-established Fischer-Tropsch reaction, in which carbon monoxide and hydrogen combine over a catalyst to produce long-chain paraffins. This advanced engineering solution enables the transformation of waste materials into high-quality SAF, to be used as part of a cleaner and more sustainable aviation industry.

Phase 2 of the process relies on the well-established Fischer-Tropsch reaction, in which carbon monoxide and hydrogen combine over a catalyst to produce long-chain paraffins. This advanced engineering solution enables the transformation of waste materials into high-quality SAF, to be used as part of a cleaner and more sustainable aviation industry.

The Avioxx Process

01

Gasification of household waste to generate clean synthesis gas

02

Generation of electricity through the use of new Solid Oxide Fuel Cells

03

Electricity generated used to produce green Hydrogen and Oxygen from water.

04

Conversion of Hydrogen and Synthesis gas into liquid fuel via the Fischer-Tropsch reactor

By 2050, 2.6 billion tons of aircraft CO2 will see an 85% net reduction, with 25,578 planes keeping their engines.

Aircraft CO2 tons by 2050

Number of aircraft

Net reduction

Replaced jet engines

Dynamic Processing and Machine Learning Enable Fuel Production Optimisation

The front-end of the Avioxx process, protected by Patent GB2431511, was initially devised as an innovative approach to generating power and hydrogen from hydrocarbons. It employs advanced technologies like gasification, fuel cells, and electrolysis to break down waste materials into their basic components. This process not only extracts valuable energy but also generates a waste stream of concentrated CO2, which can be efficiently captured and stored or repurposed for other applications, such as carbon capture and utilisation (CCU).

The back-end of the process, on the other hand, is rooted in the well-established Fischer-Tropsch reaction. This chemical process involves combining carbon monoxide and hydrogen in the presence of a catalyst, which facilitates the production of long-chain paraffins or hydrocarbons. These hydrocarbons are then refined using standard oil refinery processes, resulting in the final sustainable aviation fuel product. By combining the front-end and back-end processes, the Avioxx method effectively transforms various waste materials into high-quality, eco-friendly fuel, contributing to a more sustainable aviation industry and a greener future.