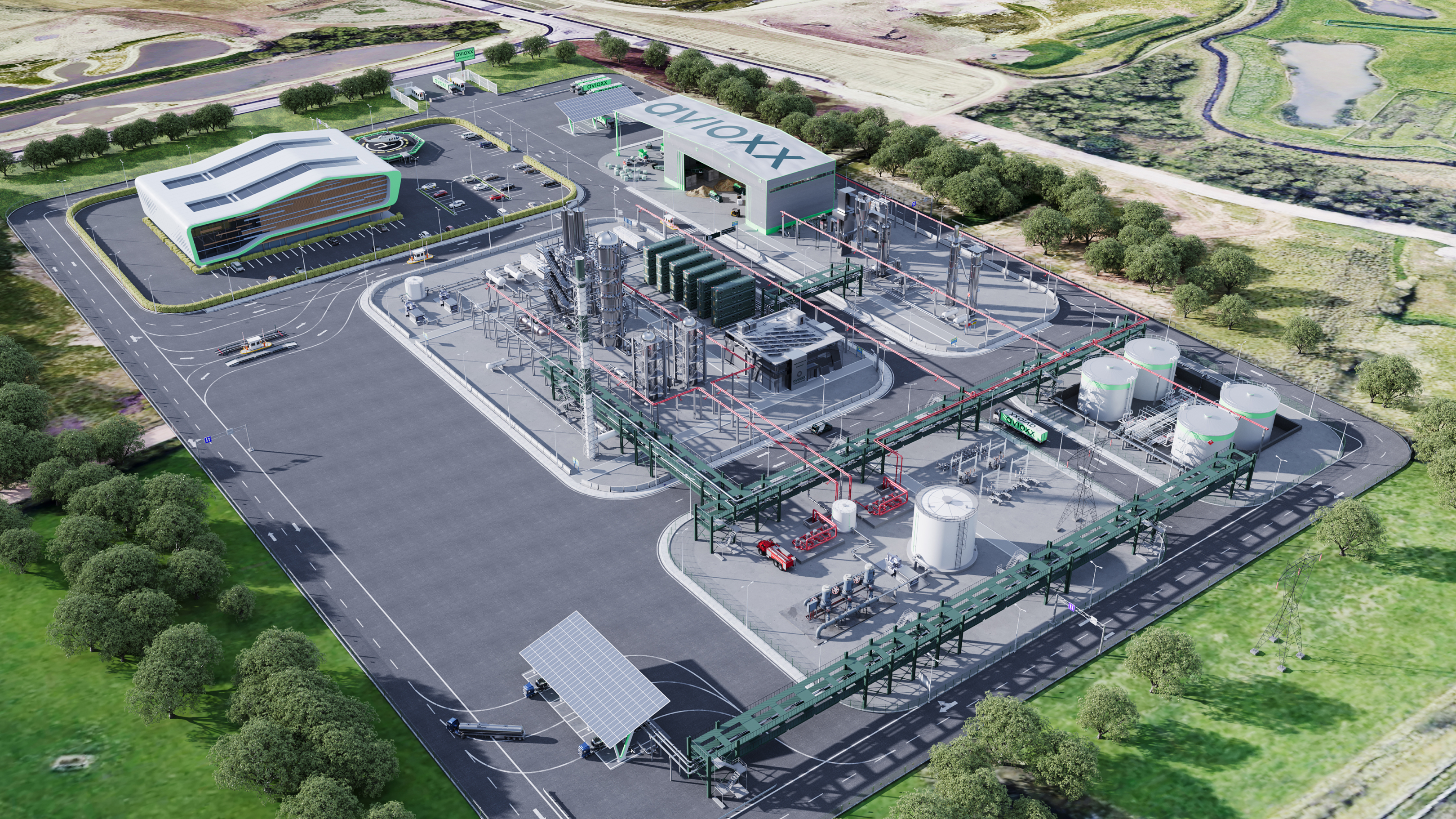

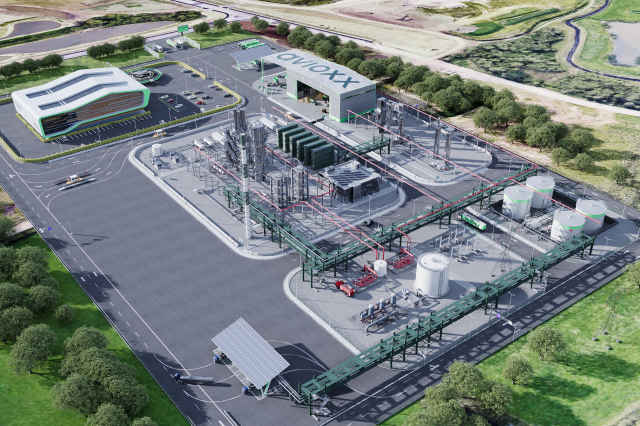

Project Genesis: 5,000 TPA Plant

Strategically located in Cheshire, it integrates seamlessly with the HyNet carbon capture infrastructure, ensuring cost effective CO2 capture and disposal.

Annual production volume

Waste processed

External energy input

CO2 reduction

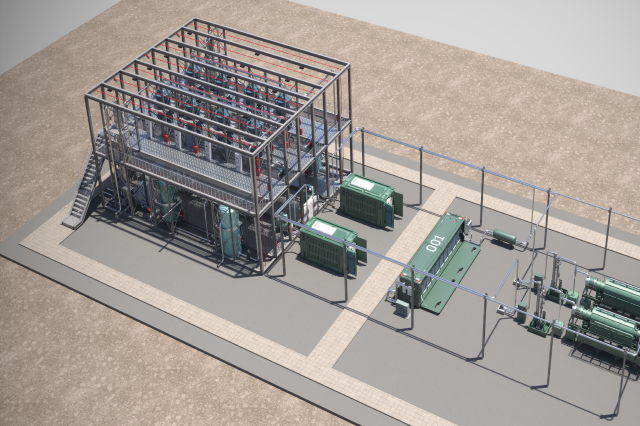

This first-of-its-kind plant integrates large-scale electrochemistry with traditional gasification and Fischer-Tropsch processes, significantly enhancing efficiency and sustainability.

Equipped with a 9 MW electrochemical system, it generates additional hydrogen to optimise gas ratios, reducing harmful emissions and byproducts. The plant is also designed for energy self-sufficiency, producing electricity within the process to lower fuel production costs and bring sustainable aviation fuel (SAF) in line with fossil-based Jet A1 pricing at scale.

By diverting waste from incineration, it will prevent 57,500 tonnes of CO2 emissions annually, making a substantial impact on climate change mitigation. This commercially viable plant serves as a scaled-down model of our full-scale 32,000-tonne-per-year facility, demonstrating the effectiveness of Avioxx’s groundbreaking technology in transforming waste into high-grade sustainable fuels.