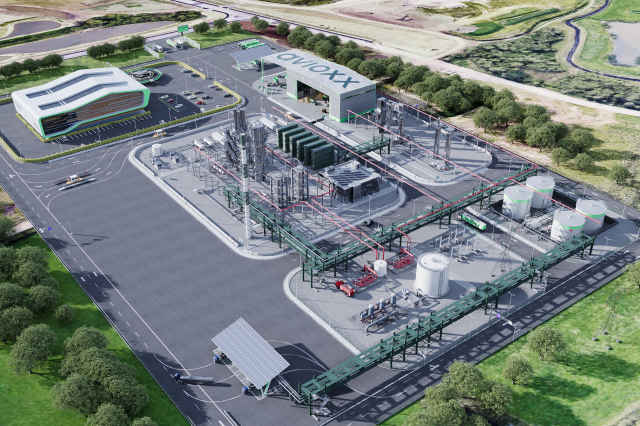

Project Catalyst: – Advanced Fuels Laboratory

Spanning 75m2, the lab houses Fischer-Tropsch, Solid Oxide Fuel Cell, Gasification, and Electrolysis systems, enabling scientists to optimise fuel production and sustainability.

Annual production volume

0.5 TPA

Primary focus

Fuel Innovation

Lab footprint

75m2

Funding

UK Govt

All statistics are estimates and subject to variation

Our primary goal is to optimise conditions for producing high-quality SAF efficiently, focusing on catalyst selection, synthesis gas composition, and reactor parameters.

Our Solid Oxide Fuel Cell research aims to improve energy conversion, leveraging AI and machine learning for greater efficiency. Situated within a historic research park in Runcorn, the lab benefits from proximity to the established petrochemical industry along the Merseyside estuary, facilitating collaboration and resource sharing.

Designed with rigorous safety measures, including four blast chambers, the lab is equipped to handle high-risk fuel innovation projects, ensuring a secure environment for groundbreaking research.

Explore the cutting-edge research driving sustainable fuel innovation at Avioxx. Our expert team thrives on solving complex challenges, pushing the boundaries of clean energy technology.

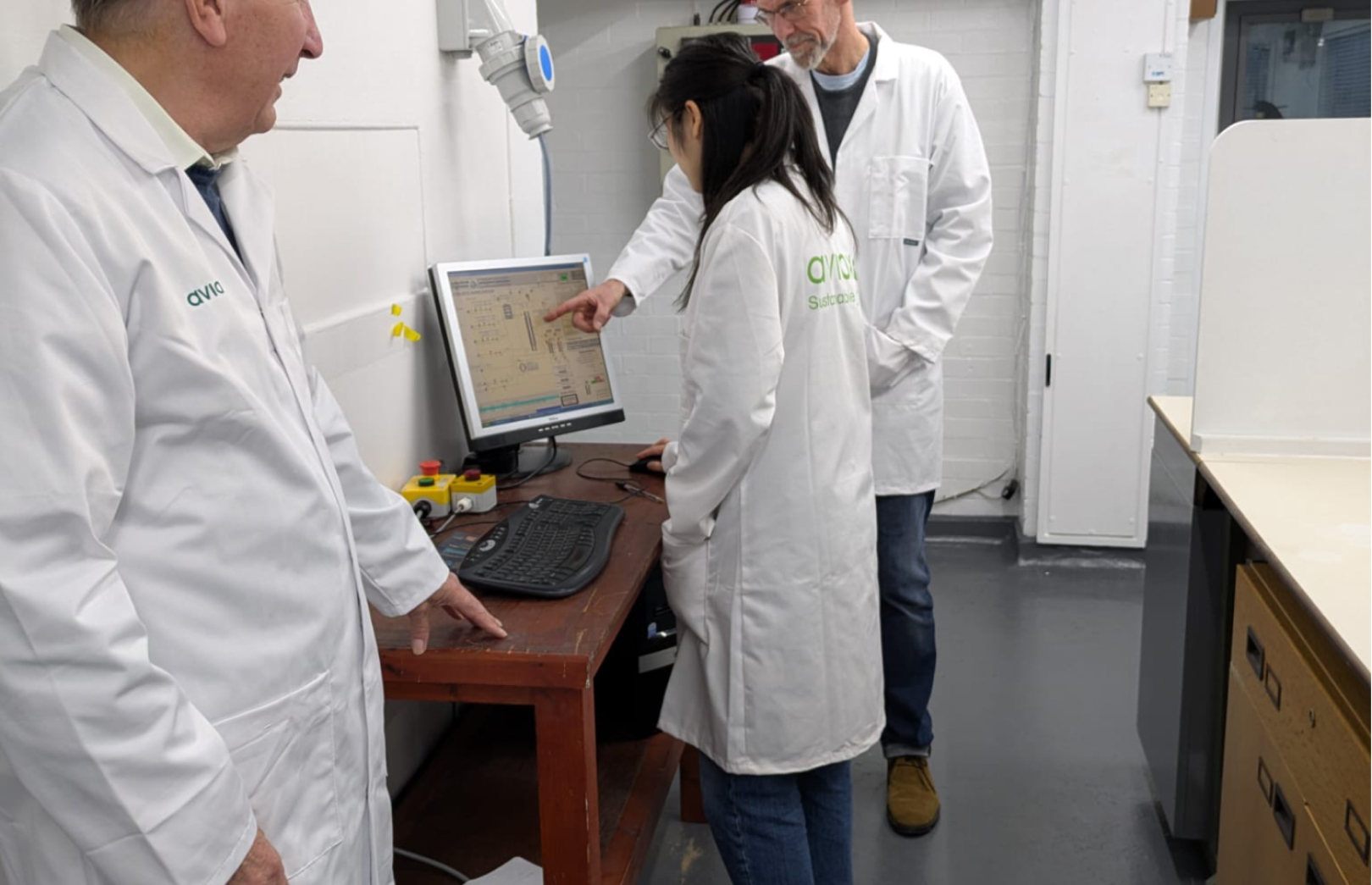

Some of the Avioxx team in one section of the lab

Some of the team reviewing the Fischer-Tropsch control system

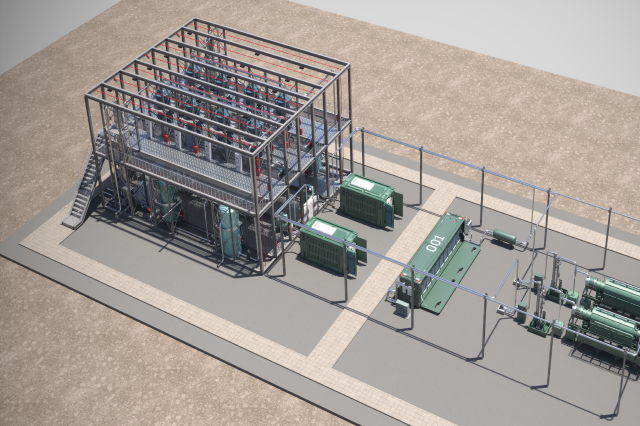

A Fischer-Tropsch reactor in one of the blast cells

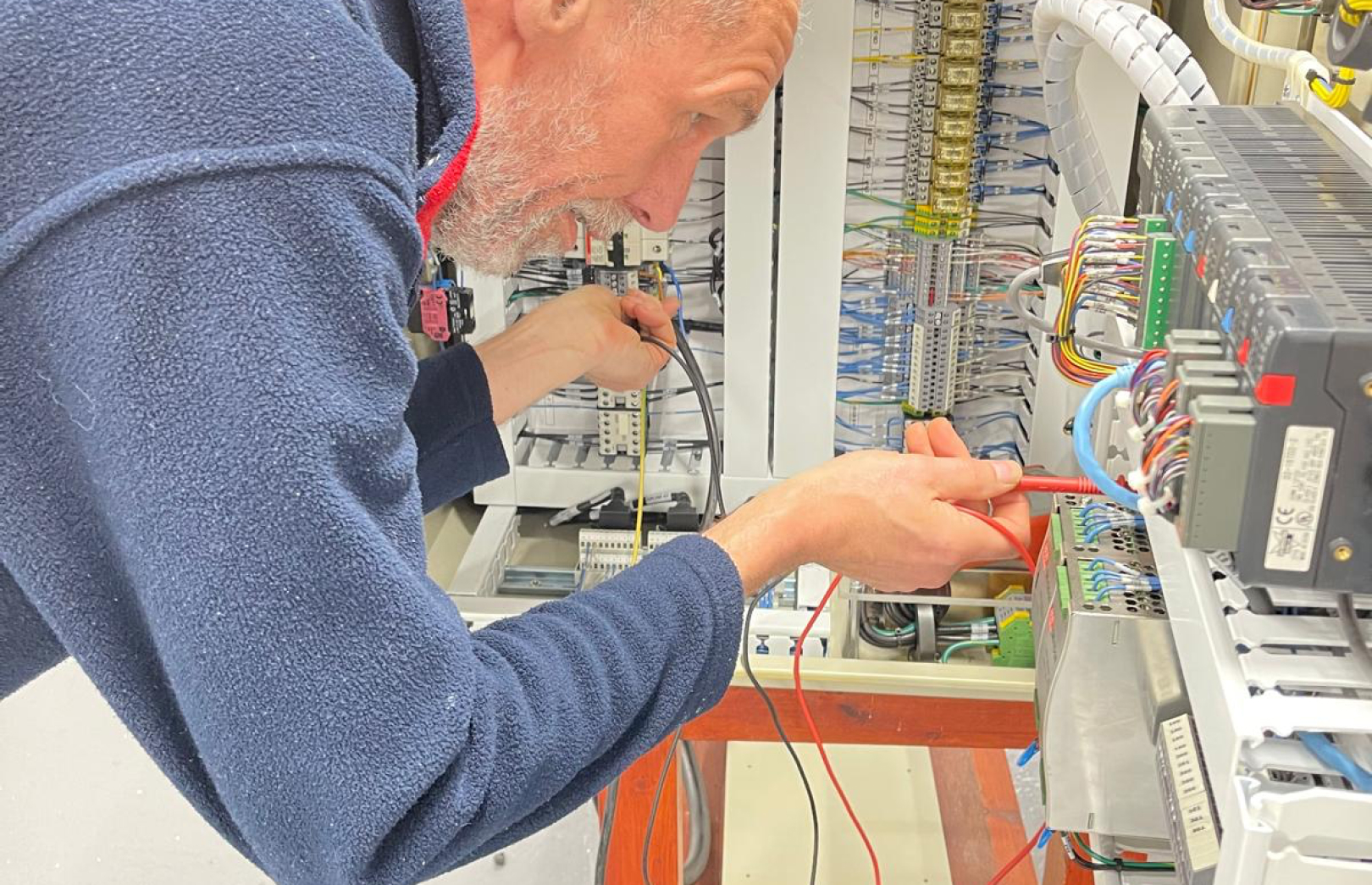

An inspection of one of the rector electronic programmable logic controllers