Lessons in failure and collaboration for the future of climate technology success

Sustainable aviation fuels (SAFs) have been recognised as the most impactful solution on the immediate path to decarbonising aviation. Airlines and governments worldwide are pledging to reach net zero by 2050, committing to the use of SAF as part of their strategies. But with recent pullbacks of planned SAF projects, how can engineers and producers ensure we can meet the growing demand of sustainable fuels?

Over the past year, we have seen several instances of SAF projects being cancelled or put on hold. To see high-profile projects — some backed by government or large multi-national firms — being withdrawn casts a shadow of doubt and uncertainty for the future of the sustainable fuels sector, but we cannot dispute the fact that transitioning from fossil to renewable sources of fuel is both a costly and complex endeavour. Understanding the challenges behind scalable solutions to SAF production can serve as an invaluable learning opportunity for current and future innovators.

Driving Success through Global Collaborations

The basis of the Avioxx waste-to-fuel process can be simplified to a two-step process: gasification and Fischer-Tropsch. Gasification involves taking sorted and pre-treated municipal solid waste (MSW) or residual household waste and partially combusting it to form syngas, a mixture of carbon monoxide and hydrogen. It is the first and the most challenging step of the process.

First, household waste is inherently inconsistent, requiring robust and flexible operating conditions of the gasification system to maintain performance. Experts in the industry recommend a high degree of pre-processing, pre-treatment and analysis in order to optimise MSW as a feedstock. The syngas resulting from waste must also be cleaned meticulously to remove impurities such as tar and sulphur compounds and obtain a pure stream of carbon monoxide and hydrogen.

Additionally, it is known that NOx can be formed during combustion with gasification at high temperature using air, leading to the creation of nitric acid, as was observed in prior waste gasification projects that have since shut down.

At Avioxx, we believe that collaboration is key to bringing novel technologies to scale. To not take lessons from projects past would be a lost opportunity to learn and improve. The climate emergency can’t afford to see more delays and monetary losses. Repeated failures erode trust with investors and hinder the progress of green solutions. There is a wealth of knowledge within the green energy industry, and technology developers must be transparent about the challenges they’ve faced so others don’t repeat the same mistakes. Knowledge transfer of both triumphs and failures is paramount for getting technologies ready for commercial success.

Furthermore, to meet the growing demand for sustainable aviation fuel, stakeholders across the value chain would benefit greatly from increased collaboration rather than working in silos. Transitioning from fossil-based jet fuel to sustainable fuel is a multifaceted problem. From technology providers and university researchers to airlines and investors, we must learn from each other to bridge knowledge gaps in how to develop commercially viable solutions for SAF production.

Our top 10 learnings to building a sustainable aviation fuel plant

- Learn from experience in the industry, there is a lot of it.

- Collaborate with partners who are proven in their field.

- Don’t re-invent the wheel just for the sake of it.

- Use the best technology available.

- Generating clean syngas is difficult.

- Having a feedstock that is high in energy is important.

- Choose a feedstock where there is enough of it.

- Iterate practical and physical hardware development quickly.

- Have a digital first approach.

- Share failures and insights with the industry.

Tackling Gasification Challenges with Engineering Solutions

Since Avioxx’s founding in 2023, our team has been actively engaged with various businesses and organisations who can support our journey in developing a first-of-a-kind (FOAK) waste-to-SAF plant. We are fostering partnerships with well-established industry leaders with whom we can exchange knowledge and expertise. Early engagement with airlines and investors has provided us with insights that inform our agile business model.

One lesson we have implemented in our development plan is to scale up incrementally, providing assurance to investors that our process can successfully produce high-quality fuel in significant quantities.

As Alex Howard (FIChemE) suggests in The Chemical Engineer,

“Instead of promising rapid, large-scale advancements, showcasing smaller, manageable achievements can prove the technology’s viability.”

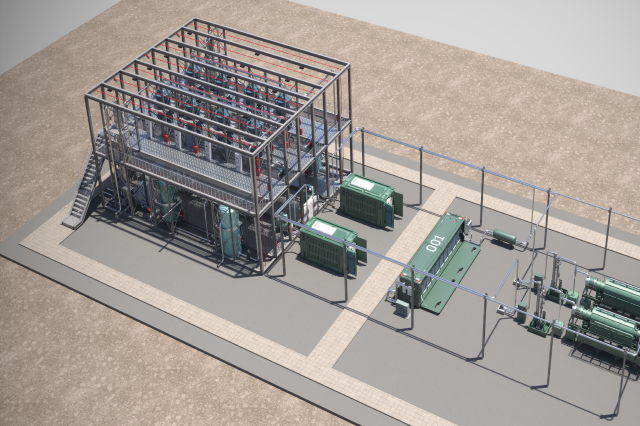

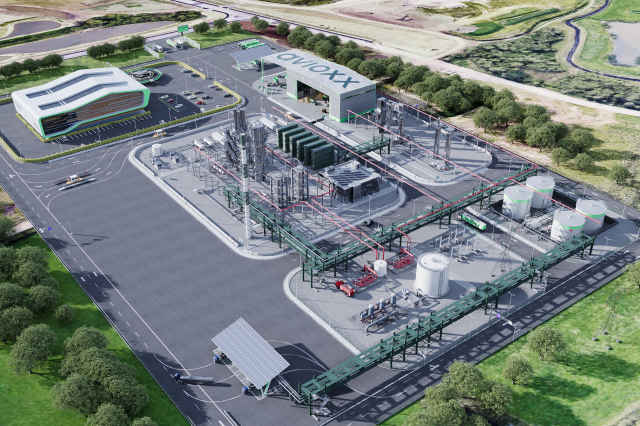

Our SAF production project will be scaled in three phases:

- A 200 tonne-per-year (TPA) capacity modular plant

- A 5,000 TPA small manufacturing plant

- A 32,000 TPA full commercial-scale plant

From a technological perspective, another challenge with municipal solid waste gasification is the fluctuating composition of the formed syngas due to its heterogeneity. For consistent product formation in the second step of the waste-to-fuel process, the Fischer-Tropsch reaction, the carbon monoxide to hydrogen ratio needs to be constant, often requiring more hydrogen to maintain. However, MSW gasification typically produces less hydrogen than required. Avioxx’s patented process addresses this issue by introducing an electrolyser to make green hydrogen from water, while the addition of solid oxide fuel cells generates electricity from syngas to power the electrolyser, eliminating reliance on external electricity.

Turning setbacks into accomplishments

Shortcomings of previously planned sustainable aviation fuel projects offer critical lessons for SAF developers and pioneering green energy projects more broadly. Innovators should anticipate potential challenges, embrace transparency in communicating obstacles and adopt an incremental approach to gain investor confidence. Engineers have a key role to play by applying their creativity, critical thinking and problem-solving skills to ensure future projects succeed, turning potential setbacks into achievements and driving sustainable advancements.

Collaboration not just within industries, but also across industries is essential for solving complex challenges like the climate crisis. We at Avioxx are developing strong partnerships to support delivery of our first-of-a-kind waste to sustainable aviation fuel manufacturing plant, and if you are interested in collaborating with us or learning more about our process, please get in touch at info@avioxx.com.