How modular designs can revolutionise sustainable fuel production

Sustainable aviation fuel (SAF) is widely recognised as a cornerstone in the global effort to decarbonise air travel. However, scaling SAF production remains a significant challenge, particularly in terms of infrastructure and feedstock logistics. By embracing modularity, small-scale SAF plants can be a key solution, leveraging localised waste streams and enhancing deployment flexibility. A novel approach to SAF production coupled with modular plant design, could be the catalyst for a new era of sustainable fuel innovation.

Traditional SAF production facilities often require substantial capital investment and centralised infrastructure. These large-scale plants are typically located near industrial hubs and often require transporting feedstocks over long distances, which can impact the overall sustainability of the process. Modularity redefines this model, providing an innovative alternative to traditional large-scale operations by enabling smaller, decentralised facilities that can be tailored to the specific needs and resources of a locality.

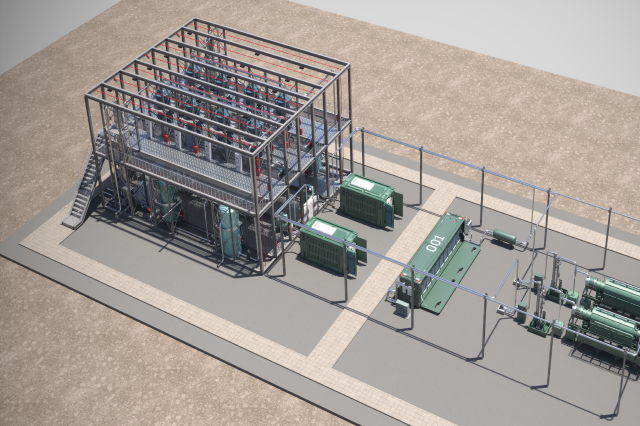

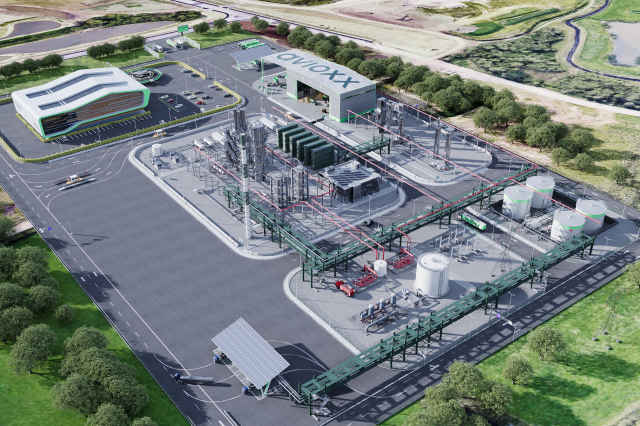

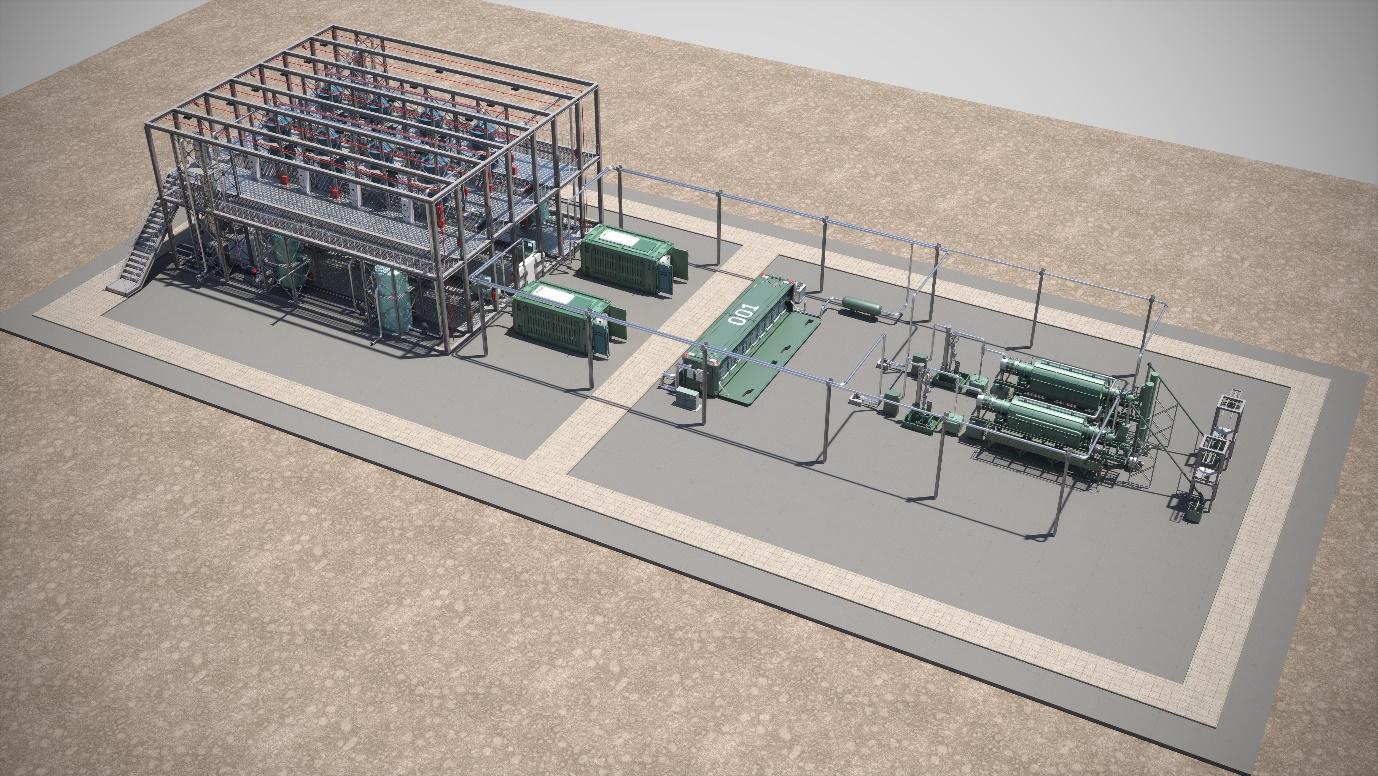

Avioxx is demonstrating the potential of this approach with their pilot-scale demonstration plant. Planned to go live by the end of 2025, this plant will produce 200 tonnes per year of SAF and 400 tonnes per year of renewable diesel and gasoline from approximately 1,800 tonnes of household waste, the primary feedstock for the Avioxx process. The modular design allows for rapid and easy deployment of fuel logistics anywhere where there is significant hydrocarbon feedstock supply or localised fuel demand. It also allows for the firm to accelerate time to market while gaining valuable insights to inform the scale-up to an interim 5,000-tonne-per-year facility and ultimately a full-scale 32,000-tonne-per-year commercial production facility.

The advantages of modularity

Small-scale modular SAF plants provide several compelling advantages. Modular units built off site allow for flexibility in location, allowing SAF production facilities to be strategically located near key infrastructure such as airports, blending facilities, or existing oil pipelines. This proximity streamlines logistics and integrates SAF into fuel supply chains efficiently. These plants can also allow for enhanced waste utilisation by tapping into municipal solid waste streams near urban centres or waste management facilities, reducing transport emissions and costs.

The scalable and replicable design of modular plants means multiple facilities can be built across different regions, creating a decentralised network of SAF production. From a financial perspective, smaller facilities require lower initial capital investment, reducing risk for investors. Moreover, modular plants can be deployed to complement centralised large-scale facilities by providing agility in revenue generation and SAF production volumes, accelerating overall progress in the SAF sector.

Building a flexible and scalable future

The success of scaling sustainable fuel production requires innovative thinking and agile business models. Starting with a smaller, modular unit provides confidence to stakeholders with a “proof-of-plant” in addition to early revenue generation from fuel sales. The ability to deploy smaller modular plants can also provide flexibility to scale production volumes, creating momentum towards large-scale operations.

Many climate tech companies and original equipment manufacturers have already recognised the benefits of modularity and are using this approach to accelerate innovation and deployment. For example, gas-to-liquid innovator INFRA Synthetic Fuels, gasification expert Compact Syngas Solutions, and Bosch’s SOFC branch, Bosch Hydrogen Energy, have all adopted modularity in their designs to streamline operations and enhance adaptability of their technologies, showcasing the growing appeal of this strategy across sectors.

As construction of their first modular demonstration plant begins later this year, Avioxx’s strategy highlights the transformative potential of decentralised SAF production alongside the development of a centralised large-scale facility. This approach could pave the way for a sustainable aviation fuel industry that not only supports global climate goals but also drives innovation in waste management and local economic development.

Modularity represents a paradigm shift for climate tech adoption. Adopting modular design for waste-to-SAF production can demonstrate how small-scale, decentralised facilities can unlock the latent potential of waste streams while fostering a cleaner, more resilient future for aviation.

For more information about the Avioxx process and modular fuel production plant, please get in touch at info@avioxx.com.