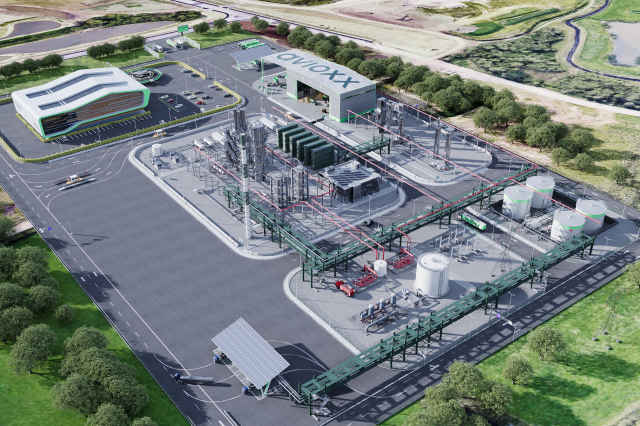

Avioxx pursues strategic partnerships for groundbreaking sustainable aviation fuel production plant

The past several months has seen a flurry of activity for the Avioxx team as they conduct in-depth assessments of potential partnerships through visits to France, Wales, and Sweden.

These key engagements are part of Avioxx’s mission to deliver a first-of-a-kind SAF production plant using their patented system to turn household waste to fuel. By rigorously evaluating state-of-the-art technologies and tapping into specialised expertise, Avioxx aims to identify the ideal partnerships that will ensure the delivery of a robust and innovative SAF facility.

AVEVA World Conference

AVEVA World, held this year in Paris from 14-17th October, focuses on transformative digital solutions for leaders and experts in industrial sectors. Avioxx was exclusively invited to this year’s event by AVEVA. Avioxx’s CEO Chris Hancock attended the keynotes from global leaders, technical sessions, and interactive learning labs where AVEVA showcased their capability to enable digital transformation, innovation, and collaboration across key industrial sectors like energy, manufacturing, and more.

Avioxx’s participation at AVEVA World 2024 underscores their commitment to leveraging digital innovation for SAF production. The event offered insights into advanced process optimisation, data analytics, and industrial software, aligning with Avioxx’s goal to integrate cutting-edge technology into their SAF plant, enhancing efficiency and environmental impact.

Visit to Compact Syngas Solutions

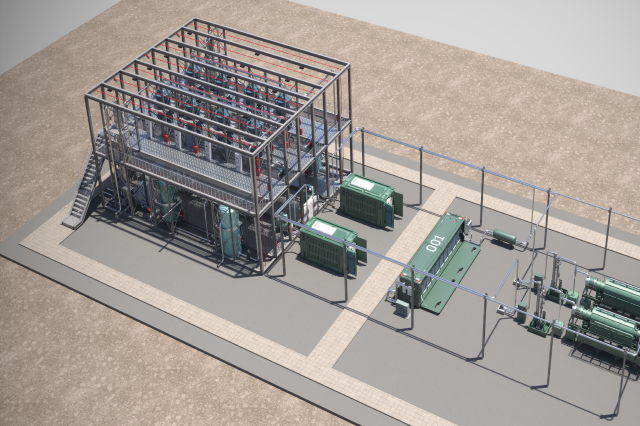

Avioxx’s engineers visited Compact Syngas Solutions (CSS)’s facility in North Wales to explore their capabilities in waste gasification. Avioxx is particularly interested in CSS’s expertise with feedstock handling and syngas processing technologies, both crucial for downstream SAF production. Their modular system is highly efficient and scalable, with its design allowing for easy dismantling and reassembly which aligns well with Avioxx’s vision of deploying flexible and reliable systems in their SAF plant.

CSS’s potential role in Avioxx’s SAF development plan could also extend beyond equipment supply. The company’s existing infrastructure, in addition to their experience in carbon capture (carbon dioxide is formed as a by-product of waste gasification) and hydrogen production, positions them as a highly suitable partner to support Avioxx’s ambition of establishing a sustainable, circular economy solution for waste management. By thoroughly evaluating CSS’s expertise, Avioxx aims to identify how this technology can integrate into their overall SAF production model.

Collaboration with Hulteberg Chemistry & Engineering

Another recent trip was made by Avioxx to visit the Hulteberg Chemistry & Engineering (HC&E) labs in Malmö, Sweden, a highly respected chemistry and engineering design laboratory headed by Professor Christian Hulteberg. In addition to delivering cutting edge research for government and large petrochemical companies they also support multiple startups in the CleanTech space. By engaging with HC&E, Avioxx can benefit from their targeted expertise in catalysis and comprehensive advisory services to assess feasibility of clean technologies. Avioxx and HC&E are currently exploring an extended partnership for the development of Avioxx’s Fischer-Tropsch (FT) systems, a key catalytic process in their synthetic fuel production pathway. During the tour, the Avioxx team reviewed HC&E’s catalyst production capacity and discussed catalyst design requirements for the Avioxx SAF plant.

HC&E’s consultancy experience and technical expertise are invaluable for ensuring optimal catalyst performance and maximising output in Avioxx’s production process. In addition, discussions on government funding and long-term collaboration highlighted both companies’ commitment to driving innovation in clean technology.

Avioxx’s Roadmap to SAF Production

Avioxx’s rigorous assessments of potential collaborators demonstrates the firm’s methodical approach to commercial SAF production. Engagements with specialised technology experts such as AVEVA, Compact Syngas Solutions, and Hulteberg Chemistry & Engineering pave the way for strategic partnerships that can provide technological depth and practical know-how. Identifying suitable partners is essential to ensure the Avioxx SAF facility will harness state-of-the-art technology, deep industry expertise, and a robust operational framework, taking steps toward the goal of scalable, efficient, and cost-effective fuel production.

Avioxx’s philosophy is about bringing the world’s leading experts together to solve the sustainable aviation challenge. If you’re interested in partnering with Avioxx, please get in touch at info@avioxx.com.